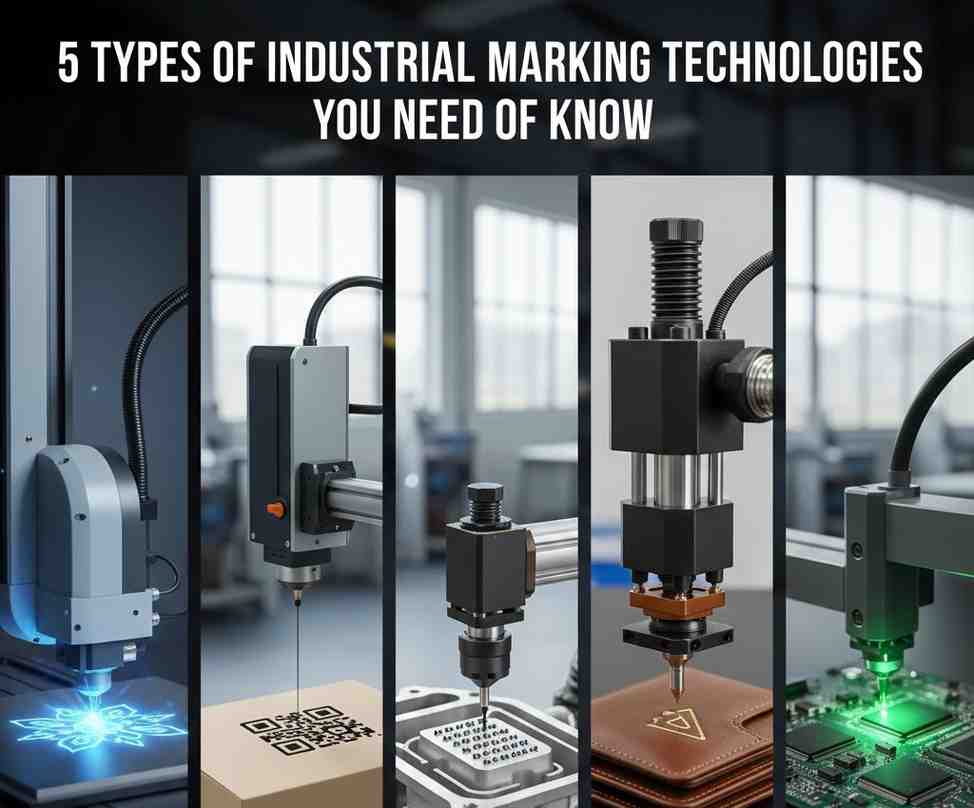

5 Types of Industrial Marking Technologies You Need to Know

Traceability is the backbone of modern manufacturing. Whether it is a serial number on an automotive engine block or a QR code on a medical device, the ability to identify and track components throughout their lifecycle is non-negotiable. Industrial marking ensures that parts meet quality control standards, adhere to strict government regulations, and can be verified for authenticity.

Dot Peen Marking

Dot peen marking is often considered the workhorse of the industry. This method uses a pneumatically or electrically driven carbide stylus to indent the surface of the material. The stylus rapidly strikes the part, creating a succession of dots that form alphanumeric characters, logos, or 2D Data Matrix codes.

Because dot peen physically displaces material rather than removing it, it creates a very durable, permanent mark that can withstand harsh environments. The marks remain legible even after painting, galvanizing, or plating, which makes this technology a favorite in heavy industries.

Key Advantages

- Durability: The marks are deep and resistant to wear, corrosion, and environmental damage.

- Cost-Effective: Dot peen systems generally have lower operating costs since they don’t require expensive consumables like ink or lasers.

- Versatility: These machines can mark on irregular or curved surfaces, provided the stylus can reach the material.

Best For: Automotive parts (VIN numbers), oil and gas pipes, and heavy machinery components made of steel or aluminum.

Laser Marking

Laser marking has gained massive popularity due to its speed, precision, and flexibility. This non-contact method uses a focused beam of light to interact with the surface of a material. Depending on the type of laser (Fiber, CO2, UV, or Vanadate) and the settings used, the beam can anneal, etch, engrave, or ablate the surface.

Laser marking creates extremely high-contrast marks that are easy for both humans and barcode scanners to read. Since there is no physical tool touching the part, there is no mechanical stress placed on the component, making it safe for delicate items.

Key Advantages

- Speed and Quality: Lasers can mark complex graphics and tiny text at incredibly high speeds with superior resolution.

- Low Maintenance: With no moving parts or consumables like ink or needles to replace, laser systems have high uptime.

- Material Range: Different laser wavelengths allow for marking on virtually anything, from metals and plastics to glass and ceramics.

Best For: Medical devices, electronics (PCBs), aerospace components, and plastic packaging.

Inkjet Marking

If you have ever looked at the “best by” date on a milk carton or the lot code on a cardboard box, you have seen inkjet marking in action. Unlike the previous methods which alter the surface of the material, inkjet marking deposits ink onto it.

There are two main types: Continuous Inkjet (CIJ) and Thermal Inkjet (TIJ). CIJ systems expel a continuous stream of ink droplets, deflecting selected ones to form characters. TIJ systems use heat to push droplets out of a nozzle only when needed. Both allow for high-speed printing on moving production lines.

Key Advantages

- Speed: Inkjet is incredibly fast and ideal for high-volume production lines.

- Non-Contact: Like lasers, the printhead does not touch the product, preventing damage.

- Surface Flexibility: It can print on porous materials (cardboard, paper) and non-porous materials (plastic, metal) with the right ink formulation.

Best For: Food and beverage packaging, pharmaceutical boxes, and wire and cable coding.

Electrochemical Etching

Electrochemical etching acts like a controlled form of rust. It uses a combination of low-voltage electricity and a mild electrolyte fluid to permanently mark conductive metals. A stencil soaked in the electrolyte is placed between an electrode and the metal part. When current flows, it oxidizes the metal surface through the stencil design, leaving a dark, high-contrast mark.

This process is unique because it removes a microscopic amount of material without creating stress points or heating the metal. This makes it crucial for safety-critical parts where structural integrity cannot be compromised.

Key Advantages

- Safety: It does not deform or weaken the metal, which is a strict requirement for certain aerospace and nuclear components.

- Aesthetics: The resulting mark is often black and very high contrast, looking almost like printing but with the durability of an etch.

- Low Cost: The equipment is relatively inexpensive and portable compared to laser or dot peen systems.

Best For: Cutlery, surgical tools, aerospace turbine blades, and bearings.

Roll Marking

Roll marking is a mechanical process that presses a hardened steel die into a part to leave an impression. It works similarly to a typewriter but with significantly more force. The part is typically supported while a round die rolls across a flat part, or a flat die rolls across a round part.

This is a contact method that relies on pressure. It is one of the fastest ways to create a deep mark, but it lacks the flexibility of computer-controlled systems like lasers or dot peen. You generally cannot change the text or serial number on the fly without changing the physical die setup.

Key Advantages

- Speed: It creates a complete mark in a single cycle, often faster than dot peen.

- Depth: It can create very deep impressions that are visible even after heavy coating processes.

- Simplicity: The machines are mechanical and robust, often lasting for decades with minimal maintenance.

Best For: Cylindrical parts like sockets, fuses, and metal bars where the data does not change frequently.

Selecting the Best Method for Your Application

Choosing the right marking technology requires balancing several factors. There is no single “best” solution, only the best solution for your specific application.

Material Compatibility

Start with what you are marking. If you are marking paper or cardboard, inkjet is the obvious choice. If you are marking hardened steel, you will likely need a fiber laser or a robust dot peen system.

Cycle Time

How fast does the production line move? Inkjet and laser marking are typically the fastest options for high-speed conveyor belts. Dot peen and electrochemical etching are slower and usually require the part to be stationary.

Budget

Consider both the initial investment and the total cost of ownership. Inkjet printers are cheaper upfront but require ongoing purchases of ink and solvent. Lasers have a high initial cost but very low operating costs.

Permanence

Does the mark need to last for 50 years on an oil pipeline, or just a few weeks on a grocery shelf? Engraving and etching methods offer permanence that surface printing cannot match.

If investing in capital equipment is not currently in your budget, or if your volume is low, you might consider outsourcing. Many companies offer industrial engraving services to handle specific marking needs without requiring you to purchase and maintain machinery.

Conclusion

The world of industrial marking is vast, but understanding the core technologies helps narrow down the field. Whether you need the deep, rugged indentation of a dot peen marker or the high-speed precision of a laser, there is a solution designed for your manufacturing line.